In the manufacturing industry, companies regularly encounter the fact that planning for different production lines is a major challenge. With a complex schedule, it is almost impossible for a single person to put together an optimal work plan. Fortunately, automation can help by combining various sources. The advantage for the entrepreneur: less time consuming and more flexible when making adjustments.

Planning and Rescheduling

Integration of existing software packages

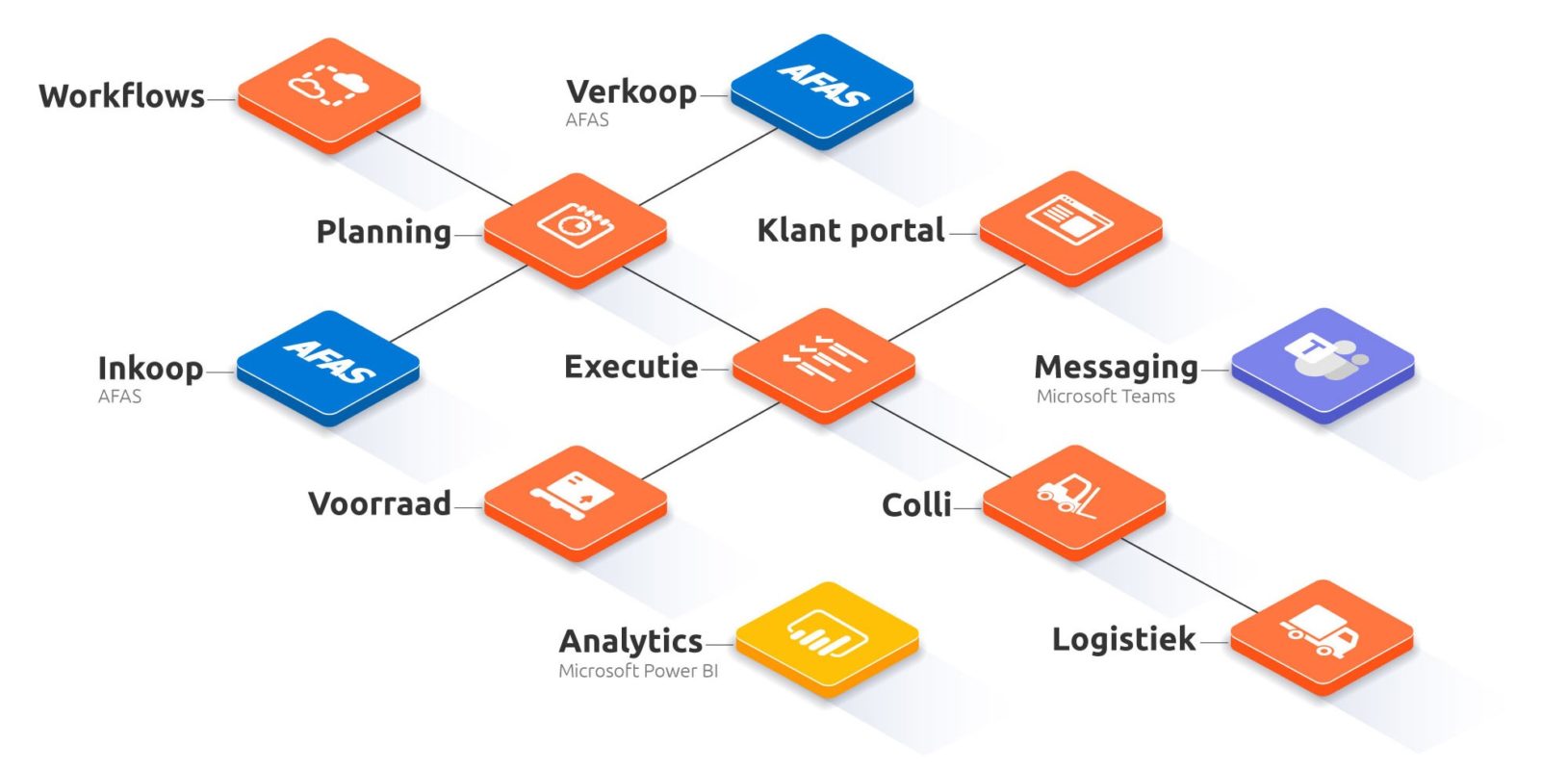

Often companies already use different software packages for creating sales orders or keeping track of inventory. These usually do not communicate with each other. BeGuru links all these data sources, processes changes immediately and brings the information together in one central point.

Want to read the whole story? Then read the beGuru case study from the injection molding industry here.

Are you curious how beGuru with their software can support your organization in the digitization/automation process?

beGuru

beGuru provides a flexible software platform that puts a smart software layer over your existing standard software. By linking beGuru with all your data sources - including your existing software packages, which normally do not exchange information with each other - all business information comes together in one place.