In 1998, a not so obscure metal band from 's-Hertogenbosch released an album titled "How to measure a planet". The band was called The Gathering, and this album was a break from their previous albums, which were filled with rather bombastic heavy metal. Bold, but they did it - and they were successful. With a startup, it's no different. At some point you have to deviate from your original plan to become successful. I remember the story of an ex-colleague at Philips who started his own company in compiler optimization. He ended up doing very different things, in the area of static code analysis. The core technology he used remained the same, but he ended up in a totally different market.

IN SHORT

This is the headline

Industry 4.0 is relevant for large and small manufacturers

This is the headline

For small manufacturers, where much of the work is still done by hand, automatic data collection is not easily possible.

This is the headline

With relatively simple technical tools, the first steps can be made, provided that it is first examined which data is really crucial for process improvement

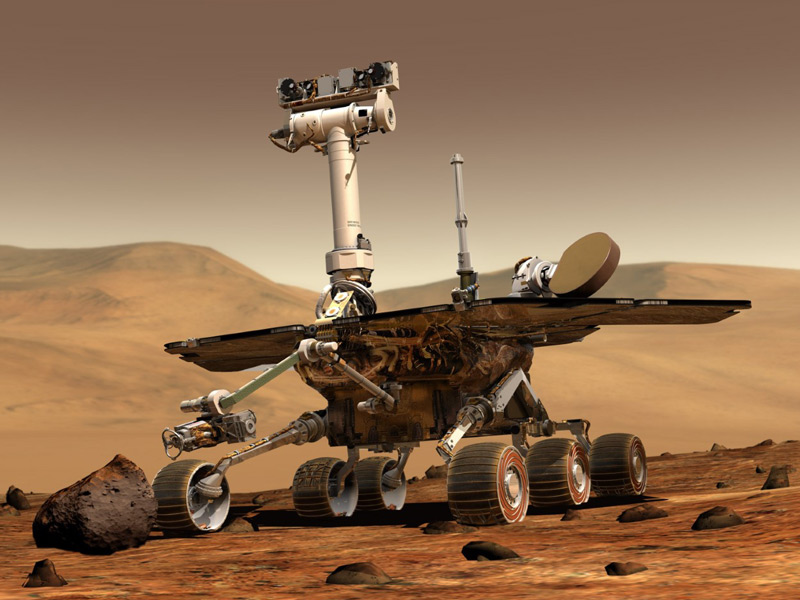

Feet on the ground

You don't make a switch like that overnight. It takes a little, or a lot, of trial and error to get to that point. That's what we're dealing with right now with Shinchoku, shortly after we started and before the first version of our website is even live.

My original idea still lives on: help small and medium-sized manufacturers optimize their production processes in a data-driven way. Or in other words: make them part of Smart Industry, Industrie 4.0. However, we now know that for this market the world looks a little different than all the fancy Industrie 4.0 videos show. There are very few robots, there is still a lot of manual labor, and although we live in the age of digitalization, many factories still have very little production management software running.

That's not necessarily a bad thing, but it requires us to determine what steps we want to take to achieve our original goal. We're not going to install an internet gateway by default, connect it to the PLCs of all the production machines, and then send the data obtained to a dashboard. That was a bit of a short version of our story anyway - you can't just collect random data and be successful, so we had to analyze with the customer what data we needed to collect before we started.

That analysis has now brought us down to earth: in most of the factories we've seen so far, there's very little data to collect initially. We need to work with the customer, with the operators in the plant, to determine which parts of the process are candidates for improvement. This must be done based on anecdotal information and experience, as there is limited support in terms of automation and reporting. Once identified, we need to determine what can be done to collect and organize data (semi-)automatically before we can start working on our actual goal.

"In a factory, for example, about 60-70% of the production process was found to be based on manual labor."

Small steps

In one factory, for example, about 60-70 percent of the production process was found to be based on manual labor. Not only are the machines operated by people, but the metal parts produced by those machines are also polished by hand. The problem in this factory is that at any point during production, no one has a record of how many parts are being processed for a given order and where they are located.

In a place like this, it is no more than a dream to switch from manual labor to full automation in one fell swoop. The reality is that we need to take small steps. The first step, in this case, could very well be the installation of wireless foot pedals at certain workstations, which operators can easily press each time they are finished with a particular part. Combined with tracking the trays in which the metal parts are transported through the plant (using RFID or something similar), this would help us get a better idea of how many parts are being produced and what stage of production they are in. Of course, this is light years away from installing a few network cables and a gateway and collecting data that is already there.

We have discussed our experiences with both customers and automation specialists from our side of the industry. They all confirm that there are some important steps that need to be taken first if we want Industry 4.0 to be within reach of smaller manufacturing companies as well. Not everyone is as big as L'Oreal or Volkswagen, where millions can be spent each year to improve automation and human labor in production has long been largely eliminated.

Process Analysis

In keeping with the song from The Gathering, we have to figure out how to measure a planet before we can actually start measuring it. That's what we're working on right now. Realizing our Industry 4.0 vision requires a number of big steps, the first of which must be taken in our market of small and medium-sized manufacturing companies.

Almost from the start, then, Shinchoku will not only be a data analytics company, but will also have to do a lot of work in the areas of process analysis and automation - almost literally to be able to generate its own data.

TIPS

This is the headline

Assume in advance that in a factory much less data is available automatically than you might initially expect

This is the headline

Make sure the process and data needs for process improvement are clear before implementing automatic data collection

shinchoku

Shinchoku, which is Japanese for "progress," is a company specializing in Smart Industry and Sustainability. Shinchoku's operations started in 2020 as a spin-off of Delphino Consultancy.