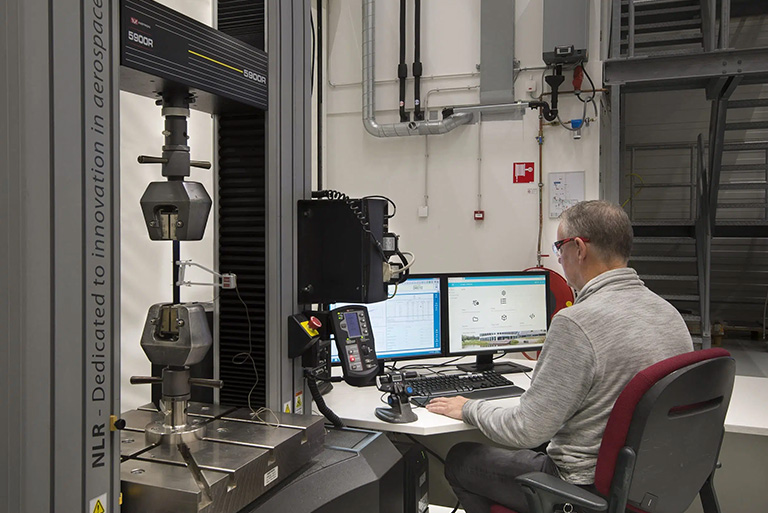

Royal NLR is the Netherlands' research center for aerospace. NLR works objectively and independently with its partners to create a better world of tomorrow. NLR has several leading research facilities, including a laboratory for mechanical testing of materials and products. These tests are done for customers all over the world and are used to determine the mechanical properties of materials and products.

The tests are performed in accordance with a standard, a standard with deviation or a compliant proprietary method. Quality assurance and efficient execution of these projects are becoming increasingly important. This will become even more important when NLR expands their work to include testing according to standard with accreditation. That will be the basis for their intended ISO 17025 accreditation. Gert Bos is happy to tell us more about how KE-chain is helping them do that.

IN SHORT

This is the headline

NLR has several leading research facilities, including a laboratory for mechanical testing of materials and products.

This is the headline

The goal of the project is to determine the mechanical properties of a composite or metal.

This is the headline

With KE-chain we can work much more efficiently. Overview, less searching for information, all information together and in combination with the linked scripts, there is much less manual work for the expert and the technical reports are now compiled automatically.

Managing coupon test projects;

lots of data and calculations

Gert has experienced all sides of mechanical testing work as an operator, project manager and nowadays also as responsible for quality assurance. Gert: "Many projects we do are coupon test programs. The goal of the project is to determine the mechanical properties of a composite or metal. We do that with tensile tests, compression tests and bending tests, which are performed with different temperatures ranging from -170 to +1500 degrees Celsius. The properties are determined according to various standards such as, ASTM, ISO, NEN-EN or customer specific standards such as the AITM standards of Airbus. This varies per customer and project just like the number of tests. This number can vary from a few dozen to more than a thousand."

Gert: "Keeping these projects manageable is quite a challenge. The work we do per project is to set up a test program, carry out the tests, assess the test results, calculate the mechanical properties and report all the results in a traceable way. Previously, each project manager did it on their own. Using large Excel tables, all the information was tracked. This created different versions of the tables with different data. We also used different scripts to send or retrieve data to the test bench and for calculating the mechanical properties. This made it confusing and took more searching to do."

"The number of tests can range from a few dozen to over a thousand. Keeping these projects manageable is quite a challenge."

Reduce variations in operating procedures,

dates and standards

NLR has been looking for some time for a solution to make these projects more manageable and thus also to reduce the variations in working methods, data and standards. Gert: "Before we started working with KE-chain, we also carefully looked at whether it had the necessary features. The fact that we can manage our own scripts is very important to us, for example. "

"We have set up KE-chain as the program to manage coupon testing programs. The new way of working with KE-chain is that everything is now centralized in one place. The work instructions are now predefined in templates, making this work per project faster and more unambiguous. The project leaders set up the project based on standard templates and can then deviate from these if the project requires it. The standard templates are divided into the various test categories that we use for our customers."

"With KE-chain we can work much more efficiently. You now have a real overview and have to search for information much less. It helps that all the information is together, such as test data and photos. In combination with the linked scripts, there is much less manual work for the expert and the technical reports are now compiled automatically."

Managing our own scripts

The layout took some time to find the right one. Gert: "You have to put in some time to make it your own. I've noticed that by now I can easily click through everything and find my information. I actually spend very little time on the KE-chain setup and can spend my time on our test specific scripts. I was also really well supported during the setup and everything was solved quickly."

"What I'm most excited about right now? That you can script. I can script randomly and actually control everything. I can really custom write the script. This helps to develop quickly and test if it works well."

TIPS

This is the headline

We have set up KE-chain as the program to manage coupon testing programs. The new way of working with KE-chain is that everything is now centralized in one place. The work instructions are now predefined in templates, making this work per project faster and more unambiguous.

This is the headline

With KE-chain we can work much more efficiently. You now have a real overview and have to search for information much less. It helps that all the information is together, such as test data and photos. In combination with the linked scripts, there is much less manual work for the expert and the technical reports are now compiled automatically.

This is the headline

The layout took some time to find the right one. Gert: "You have to put in some time to make it your own. I've noticed that by now I can easily click through everything and find my information. I actually don't spend much time on the KE-chain setup and can spend my time on our test specific scripts.

KE-works

KE-works provides KE-chain; a cloud-based application platform for digital engineering and operations to customers in aerospace, automotive, infrastructure and high tech. KE-chain applications are flexible, simple and smart.